I. Overview of the Truck's Rotating System

The rotating system of a truck represents a pivotal component, ensuring the vehicle's capacity to execute functions such as seamless driving and precise steering. It efficiently transfers the engine's power to the wheels while safeguarding the vehicle's operational stability and reliability across diverse road conditions.

II. Main Components of the Rotating System

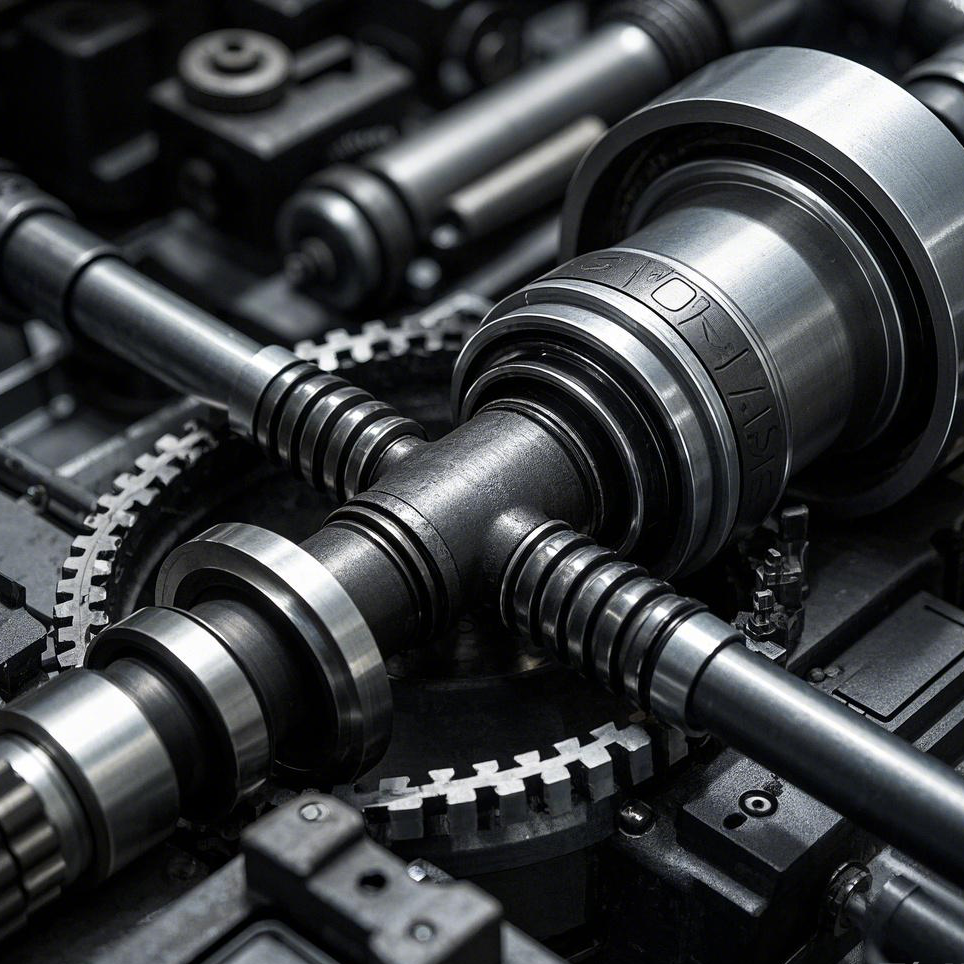

Drive Shaft

The drive shaft serves as a critical element linking the engine and the drive axle. Its primary function is to convey the engine's power to the drive axle. Comprising a universal joint, a telescopic sleeve, and a shaft tube, the drive shaft is designed for optimal power transmission. The universal joint enables power transfer at varying angles, accommodating the relative positional shifts among components during vehicle operation. The telescopic sleeve allows the drive shaft to exhibit a certain degree of telescopic motion along its length, compensating for length variations induced by vehicle frame deformation and assembly discrepancies during driving.

Drive Axle

The drive axle mainly consists of the main reducer, differential, half shafts, and the axle housing. The main reducer functions to decelerate the rotational speed and amplify the torque, catering to the truck's driving force demands under different driving scenarios. The differential empowers the left and right wheels to rotate at disparate speeds during turns, ensuring smooth vehicle steering. The half shafts transmit the differential's power to the wheels, and the axle housing acts as the mounting base for components like the main reducer, differential, and half shafts, while concurrently providing support and protection.

The wheel hub is an essential component connecting the wheels and the axles. Bearing the truck's weight, it also forms the rotational part of the wheels in conjunction with the tires. Wheel hub materials are typically categorized into aluminum alloy and steel. Aluminum alloy wheel hubs are characterized by their lightweight nature and excellent heat dissipation properties, albeit at a relatively higher cost. Conversely, steel wheel hubs possess high strength and lower costs.

Steering Knuckle

The steering knuckle represents a crucial element of the steering axle. Collaborating with the kingpin, wheel hub, etc., it facilitates the wheels' steering function. During vehicle operation, the steering knuckle endures diverse forces such as vertical, braking, and lateral forces, necessitating high strength and toughness.

Universal Joint

Beyond the universal joints installed on the drive shaft, they are also integral to the steering system. Capable of transmitting power in various directions, they ensure the accurate conveyance of the steering wheel's rotation to the steering gear, guaranteeing the vehicle's steering flexibility.

III. Maintenance Key Points of the Rotating System Components

Maintenance of the Drive Shaft

Regularly inspect the tightness of the drive shaft's

bolts and nuts. In the event of looseness, promptly tighten them. Examine the universal joint's clearance; an excessive clearance may result in abnormal transmission noise and vibration, warranting immediate replacement of the universal joint. Additionally, monitor whether the drive shaft's telescopic sleeve is jammed, and conduct lubrication if required. Typically, lubricate the drive shaft's lubrication points every 10,000 - 20,000 kilometers.

Maintenance of the Drive Axle

Regularly check the oil level of the drive axle's lubricating oil to ensure adequacy. Insufficient lubricating oil can lead to heightened wear of components such as the main reducer and differential. Replace the drive axle's lubricating oil every 40,000 - 60,000 kilometers. Simultaneously, assess the quality of the lubricating oil; if it has deteriorated or contains metal debris, etc., replace it ahead of schedule. Moreover, inspect the operational status of the main reducer and differential. In case of abnormal noises or overheating, conduct maintenance without delay.

Frequently verify the tightness of the wheel hub's bolts to prevent wheel detachment during driving. Regularly clean the dirt and rust on the wheel hub's surface to maintain its cleanliness. Also, check for cracks or deformations in the wheel hub. If any issues are detected, replace it promptly. For aluminum alloy wheel hubs, refrain from using highly corrosive cleaners to avoid surface damage.

Maintenance of the Steering Knuckle

Regularly inspect the steering knuckle's kingpin clearance. An excessive clearance may lead to unstable steering during vehicle operation. Check the lubrication condition of the steering knuckle and replenish the lubricating grease in a timely manner. During vehicle operation, if abnormal steering phenomena such as heavy steering or deviation occur, promptly examine the steering knuckle and related components.

Maintenance of the Universal Joint

For the universal joints in the steering system, regularly check the tightness of the connection parts and the flexibility of rotation. If the universal joint is severely worn or jammed, replace it immediately. Additionally, pay attention to its lubrication. Generally, lubricate it every 20,000 - 30,000 kilometers.

IV. Importance of Maintaining the Rotating System

Proper maintenance of the rotating system can extend the truck's service life, mitigate component wear and damage, and reduce maintenance costs. Simultaneously, ensuring the rotating system's normal operation enhances the vehicle's driving safety and stability, minimizing traffic accidents attributable to rotating system malfunctions. Moreover, regular maintenance of the rotating system can improve the vehicle's fuel economy, as smooth power transmission alleviates the engine's load, thereby reducing fuel consumption.

In summary, maintaining the components of the truck's rotating system is an essential task. Truck drivers and maintenance personnel should fully recognize its significance and conduct inspections and maintenance in strict accordance with the maintenance requirements and intervals to ensure the truck's rotating system remains in optimal working condition.

Xingtai Guangji Machinery Technology Co.,Ltd also produce casting and machining products which apply to heavy duty trucks,agricultural machinery & con- struction machinery, Leading products : axles, wheel hub, Brake Drum ,Brake Shoe, Leaf Spring bracket,transmission box, cylinder block, cylinder head etc. 50% of our products is customized by drawing or sample. Different material of our goods contains gray iron, ductile iron, vermicular graphite iron, steel & alu-minum alloy, Sand casting, precoated sand casting.lost foam casting, mould opening, CNc machining, aluminum die-casting are acceptable. With advanced equipment and test machine including CNC vertical machining center, Three-coordinates measuring machine etc. We promise that our quality is qualified and meet standard ASTM,BIN, JIS.BS etc."Quality as a way of life" is our eternal belief.