Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

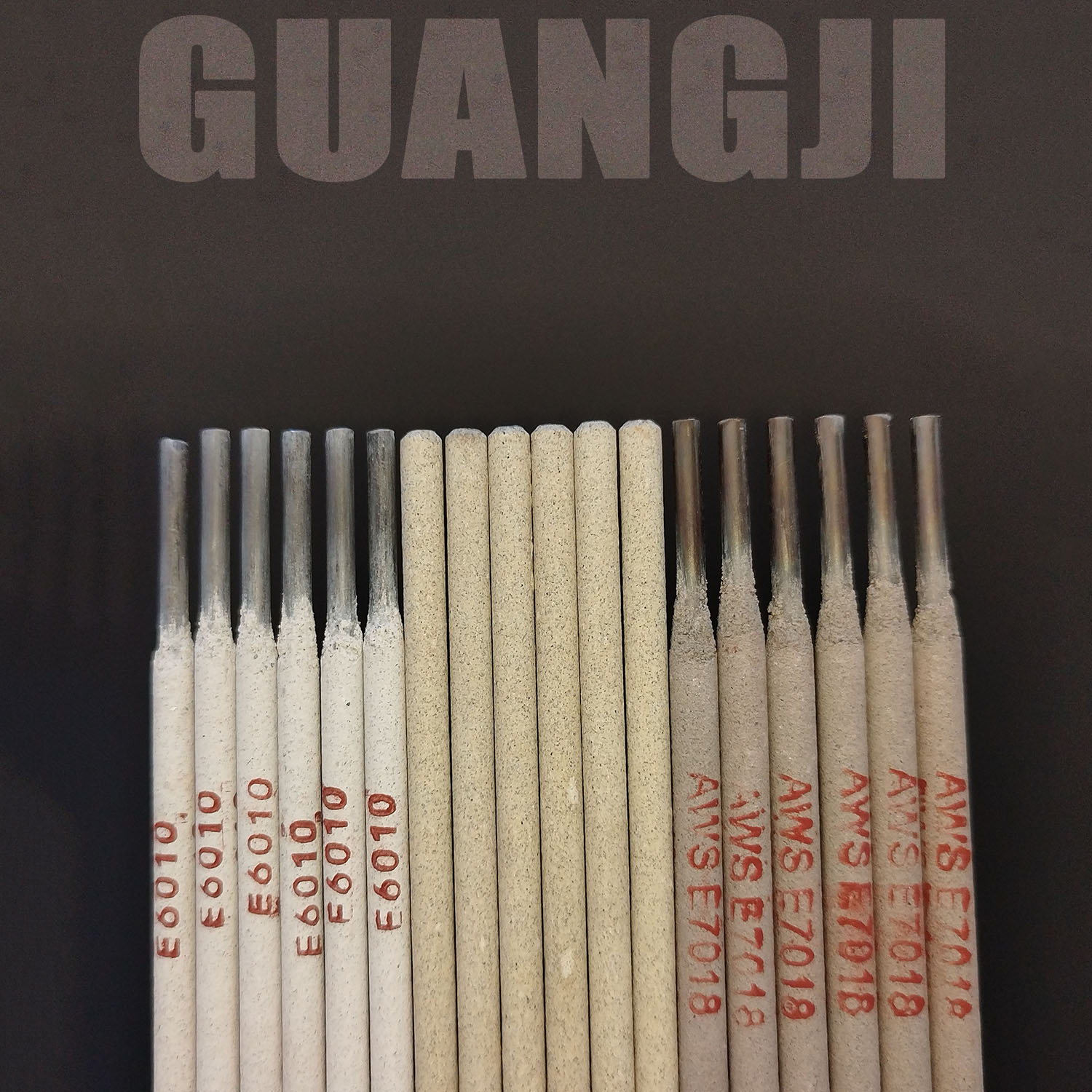

Welding electrodes primarily consist of two components: the core wire and the flux coating.

Core Wire

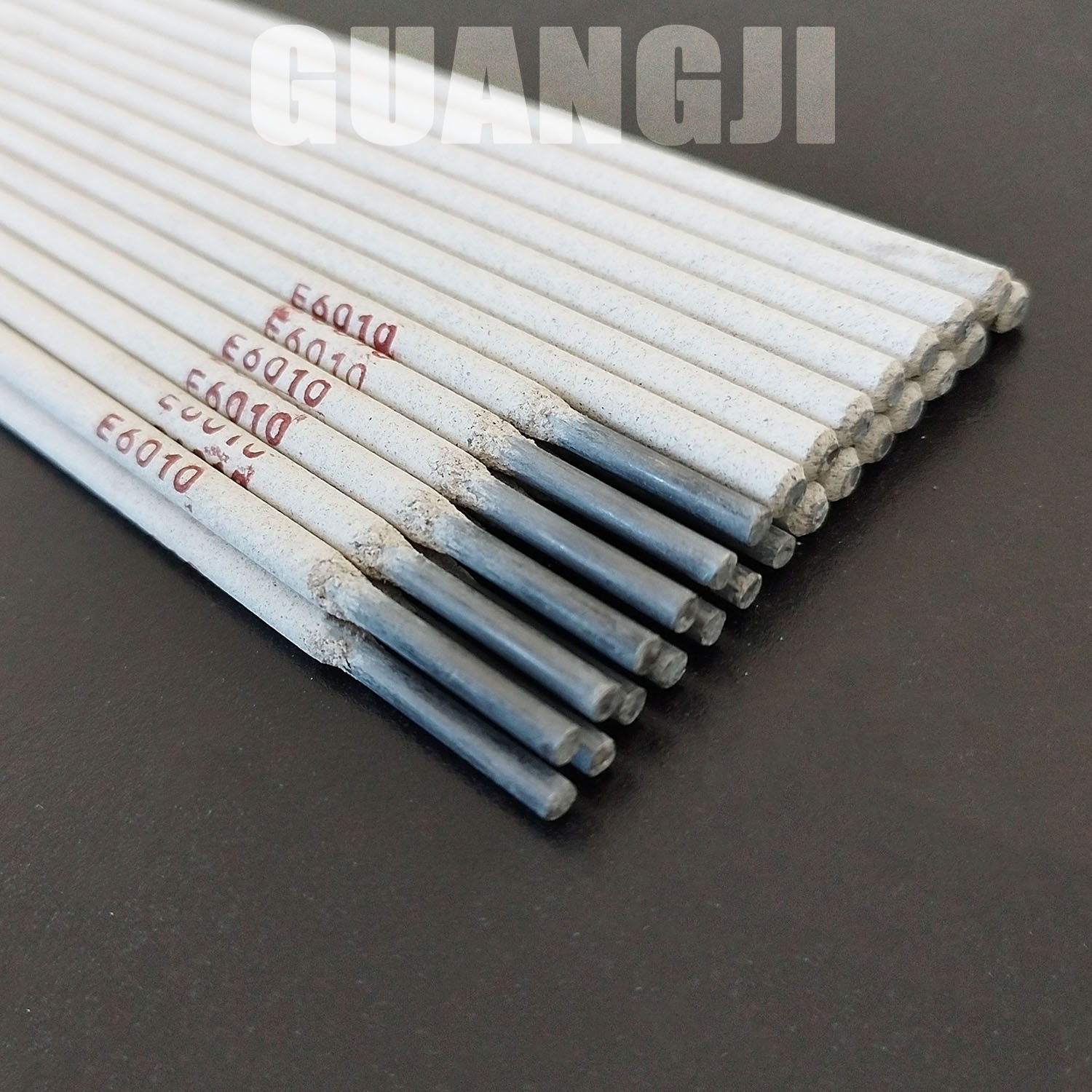

Definition and Functions: The core wire is the metal wire enveloped by the flux coating in a Welding electrode. It serves two main purposes. Firstly, it acts as an electrode to conduct electric current, facilitating the establishment of a welding circuit and thus generating an arc between the welding electrode and the workpiece. Secondly, it functions as a filler metal. During the welding process, it melts and fuses with the base metal of the workpiece to jointly form a weld seam.

Material Selection: The material of the core wire is typically determined according to the material of the workpiece's base metal. For instance, when welding ordinary low-carbon steel, low-carbon steel welding wires like H08A and H08E are commonly employed as the core wire. These low-carbon steel core wires contain a small quantity of elements such as carbon (generally less than 0.1%) and manganese (0.3 - 0.55%) to ensure excellent welding performance and weld seam quality. For welding alloy steels, the composition of the core wire will be adjusted in accordance with the specific composition of the alloy steel to match the alloy element content of the base metal, enabling the weld metal to have performance similar to that of the base metal.

Specifications and Dimensions: The core wire comes in various diameter specifications, including 2.0mm, 2.5mm, 3.2mm, 4.0mm, 5.0mm, and others. In actual welding, the selection of the core wire's diameter mainly depends on factors such as the thickness of the workpiece, the welding position, and the magnitude of the welding current. For example, for thinner workpieces (with a thickness less than 3mm), a core wire with a smaller diameter (such as 2.0mm or 2.5mm) is generally chosen so that a smaller welding current can be used to avoid burning through the workpiece. Conversely, for thicker workpieces, a core wire with a larger diameter and a corresponding larger welding current need to be selected to ensure complete penetration.

Flux Coating

Definition and Functions: The flux coating is a coating layer pressed onto the surface of the core wire. It plays a crucial role in the welding process, mainly in aspects such as stabilizing the arc, protecting the molten pool, deoxidizing, and alloying.

Components and Functions:

Arc Stabilizer: Its main function is to enable the arc to ignite easily and burn stably. Common components of arc stabilizers are compounds of potassium and sodium, such as potassium carbonate (K₂CO₃) and sodium carbonate (Na₂CO₃). Under an alternating current arc welding power supply, due to the periodic change of current direction, the arc stability is relatively poorer compared to that of a direct current arc welding power supply, and the role of the arc stabilizer becomes more evident. For example, in some low-hydrogen electrodes, adding an appropriate amount of arc stabilizer can enhance the stability of the alternating current arc, facilitating welding operations.

Slag Forming Agent: It is mainly utilized to form slag during the welding process, covering the surface of the weld seam to protect the weld metal from the encroachment of harmful gases like oxygen and nitrogen in the air. Common slag forming agents include ilmenite (FeTiO₃), rutile (TiO₂), marble (CaCO₃), and so on. Taking a rutile-calcium type electrode as an example, the rutile in it melts under the high temperature of welding to form slag. This slag has good fluidity and covering ability and can effectively isolate the air to prevent the formation of pores and slag inclusions in the weld seam.

Gas Forming Agent: It decomposes when heated to generate gas, forming a protective atmosphere around the arc to further isolate the air. Organic substances such as starch and cellulose are common gas forming agents. During the welding process, these organic substances decompose when heated to produce gases such as carbon dioxide and hydrogen, forming a gas protective layer around the arc to prevent the contact between the harmful components in the air and the molten metal. For example, in a cellulose type electrode, the large amount of gas produced by the decomposition of cellulose can provide excellent gas protection in special welding environments such as narrow-gap welding.

Deoxidizer: It is used to remove oxygen from the weld metal. Since oxygen will form oxide inclusions in the weld seam, reducing the mechanical properties of the weld seam. Common deoxidizers are ferroalloys such as ferromanganese (FeMn) and ferrosilicon (FeSi). During the welding process, the deoxidizer reacts with the oxygen in the weld metal to generate oxides that are insoluble in the weld metal and float into the slag to be removed. For example, the manganese element in ferromanganese can react with the oxygen in the weld metal to generate MnO, which enters the slag, thereby improving the quality of the weld metal.

Alloying Agent: To make the weld metal obtain performance similar to that of the base metal or special performance (such as higher strength, better corrosion resistance, etc.), alloying agents will be added to the flux coating of the welding electrode. For example, when welding stainless steel, the flux coating will contain alloying agents with alloy elements such as chromium (Cr) and nickel (Ni) to ensure that the weld metal has corrosion resistance equivalent to that of the stainless steel base metal. Additionally, when welding high-strength alloy steel, alloying agents such as molybdenum (Mo) and vanadium (V) will be added to improve the strength and toughness of the weld.

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.