What is a Engine Cylinder Block?

2024,12,27

The cylinder block constitutes a crucial component within an engine, possessing the following principal characteristics and fulfilling diverse functions:

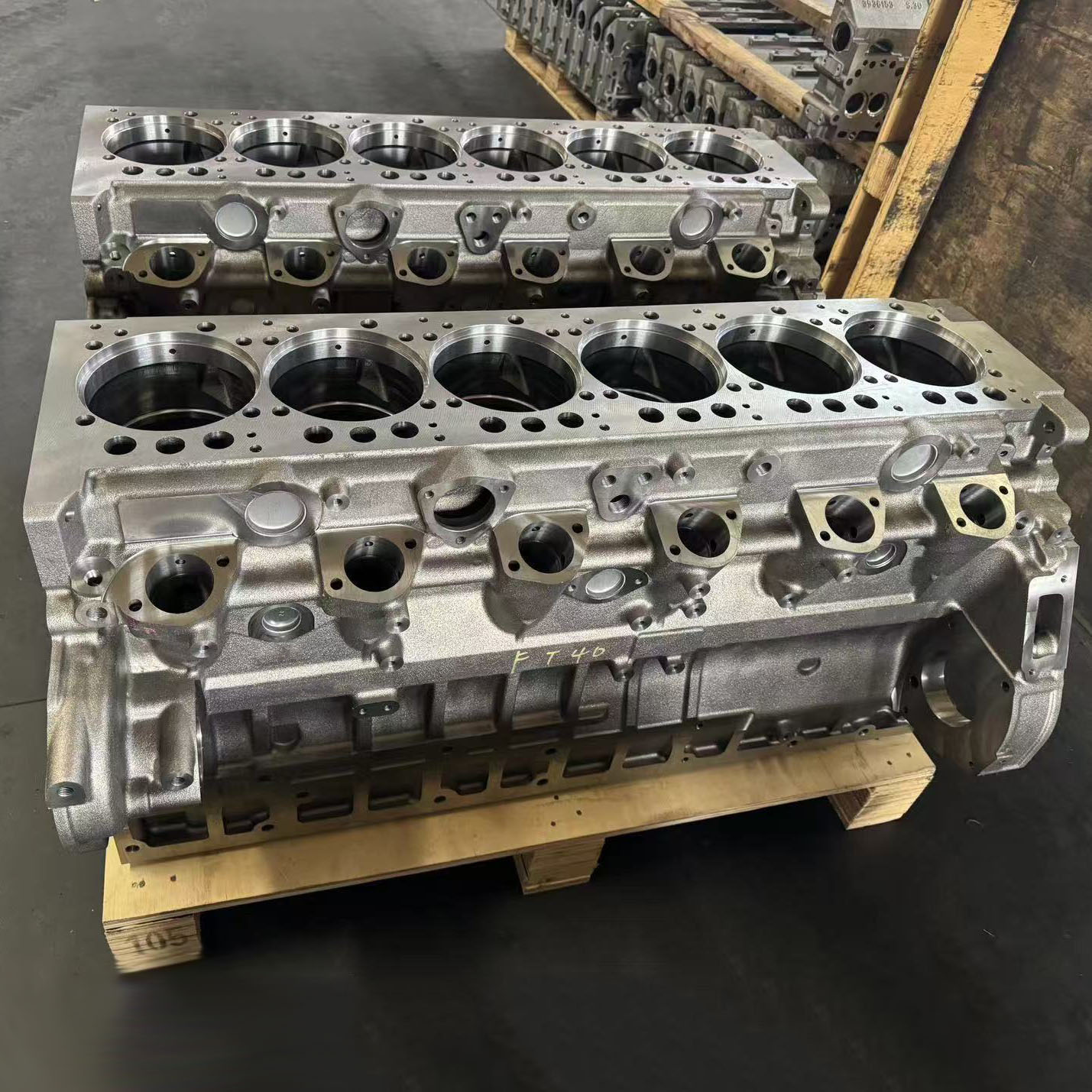

Structure and Composition:Typically, the cylinder block presents itself as a solid metallic structure, commonly fabricated from either cast iron or aluminum alloy. Internally, it houses multiple cylindrical chambers known as cylinders, which serve as the arenas for the pistons' reciprocating motion. The lower portion of the cylinder block forms the crankcase, tasked with providing support to the crankshaft, while its inner cavity accommodates the movement of the latter. Moreover, a plethora of reinforcing ribs, cooling water jackets, as well as lubricating oil passages are integrally cast within the cylinder block.

Function:It functions as the fundamental supporting framework for the installation of pistons, crankshafts, and other associated components and accessories. During engine operation, it endures a variety of loads, including high temperatures, elevated pressures, vibrations, and impacts. The individual cylinders are meticulously arranged within the block and collaborate harmoniously with components like pistons and connecting rods. This synergy converts the energy of the combusted gas into mechanical energy, thereby driving the crankshaft to rotate and supplying power to the vehicle. Concurrently, by means of structures such as cooling water jackets or cooling fins, it facilitates the dissipation of heat generated during engine operation, ensuring that the engine remains within the normal operating temperature range.

Common Types:Based on the arrangement of cylinders, it can be categorized into in-line, V-type, and opposed configurations. The in-line cylinder block features a straightforward structure and is relatively straightforward to manufacture, albeit resulting in a comparatively larger engine length and height. The V-type cylinder block curtails the engine's length and height, augments its rigidity, and reduces overall weight, though its shape is more intricate and presents greater processing challenges. The opposed cylinder block exhibits a low height, which is conducive to overall layout and advantageous for air cooling, yet it is less frequently employed. In terms of the structural form of cylinders, it can be divided into integral cylinder and cylinder liner type. The cylinder liner type can be further subdivided into dry cylinder liner and wet cylinder liner.